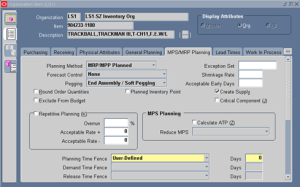

MPS/MRP planning attributes

Navigation path: Inventory>Items>Master Items>General Planning (T)

Refer to the table below for the setup of each attribute.

| Attribute | Valid

values |

Purpose | Comment | Setup |

| Planning | Not | Select the option | Not Planned: The item does not | |

| Method | Planned, | that Planning | require long–term planning of | |

| MRP | uses to decide | material requirements. Choose this | ||

| planning, | when to plan the | option for high volume and/or low | ||

| MPS | item | cost items that do not warrant the | ||

| planning, | administrative overhead of | |||

| MRP/DRP | planning; typically dependent | |||

| Planned, | demand items. You cannot use this | |||

| MPS/DRP | option unless the Pick Components | |||

| Planned, | attribute is checked. | |||

| DRP | MRP planning: Choose this option | |||

| Planned | for non–critical items that do not | |||

| require manual planning control, | ||||

| typically dependent demand items. | ||||

| MPS planning: You master | ||||

| schedule the item and require | ||||

| manual planning control. Choose | ||||

| this option for items with | ||||

| independent demand, items that are | ||||

| critical to your business, or items | ||||

| that control critical resources. | ||||

| MRP/DRP Planned: Choose this | ||||

| option when you want both MRP | ||||

| and DRP planning for the item. | ||||

| MPS/DRP Planned: Choose this | ||||

| option when you want both MRP | ||||

| and DRP planning for the item. | ||||

| DRP Planned: Choose this option | ||||

| when you have multiple | ||||

| organizations for which you do | ||||

| Distribution Requirements | ||||

| Planning for the item. | ||||

| Forecast | Consume, | Select an option | This is appropriate only for items | |

| Control | Consume | to determine the | that are models, option classes, | |

| and derive, | types of demand | options, or mandatory components | ||

| None | you place for the | of models and option classes. | ||

| item. This guides | Consume: forecast demand | |||

| the key processes | directly, rather than by exploding | |||

| of two–level | forecast demand. | |||

| master | Consume and derive: forecast | |||

| scheduling: | demand directly, explode forecast | |||

| forecast | demand, or use a combination of | |||

| explosion, | both methods. | |||

| forecast | None: place sales order demand | |||

| consumption, | but do not forecast demand. | |||

| planning, | ||||

| production relief, | ||||

| and shipment | ||||

| relief. |

| Attribute | Valid

values |

Purpose | Comment | Setup |

| Exception Set | Enter the name | The item–level planning | ||

| of the planning | exceptions include: | |||

| exception set that | overcommitted, shortage, excess, | |||

| groups together | and repetitive variance. The | |||

| the sensitivity | planning process uses this attribute | |||

| controls and | to decide when to raise planning | |||

| exception time | exceptions for the item. | |||

| periods for item– | ||||

| level planning | ||||

| exceptions for | ||||

| the item. | ||||

| Create | Indicates if | |||

| Supply | supply can be | |||

| suggested for this | ||||

| item. | ||||

| Critical | If selected, flags | This allows you to plan master | ||

| Component | the item as a | scheduled items with respect to | ||

| critical | only critical component and their | |||

| component for | material resource constraints. | |||

| MPS and DRP | ||||

| planning. | ||||

| Pegging | Soft | Enter the pegging | Soft Pegging: allocates supply to | |

| Pegging, | option. | demand based on the Reservation | ||

| End | Level option set in the Plan | |||

| Assembly | options. | |||

| Pegging, | End Assembly Pegging: traces the | |||

| End | end assembly the item is pegged to | |||

| Assembly/ | at the top of the bill of material. | |||

| Soft | Even if you do not select end | |||

| Pegging, | assembly pegging, you can still | |||

| Hard | calculate and view end assemblies | |||

| Pegging, | on–line. | |||

| End | End Assembly/ Soft Pegging: | |||

| Assembly/ | Choose this option for both soft | |||

| Hard | pegging and end assembly | |||

| Pegging, | pegging. | |||

| None | Hard Pegging: allocates supply to | |||

| demand based on the Reservation | ||||

| Level option set in the Plan | ||||

| options. This pegs supply to | ||||

| demand and demand to supply by | ||||

| project at all levels of a bill of | ||||

| material. This allows you to pre– | ||||

| allocate supply to demand and | ||||

| generate planned orders based on | ||||

| the plan level options. | ||||

| End Assembly/ Hard Pegging: | ||||

| Choose this option for both hard | ||||

| pegging and end assembly | ||||

| pegging. | ||||

| None: disables project material | ||||

| allocation, end assembly pegging, | ||||

| and full pegging. | ||||

| Planned | Indicates if the | This means that material can be | ||

| Inventory | item is an | stored at the item level without | ||

| Point | Inventory Point | losing materials or quality | ||

| item. | characteristics. Inventory Points | |||

| generally point to major stocking | ||||

| phases in the manufacturing cycle. |

| Attribute | Valid

values |

Purpose | Comment | Setup |

| Shrinkage | Enter a factor | The planning process inflates | ||

| Rate | that represents | demand to compensate for this | ||

| the average | expected loss. | |||

| amount of | ||||

| material expected | ||||

| to lose during | ||||

| manufacturing or | ||||

| in storage. | ||||

| Round Order Quantities 1 | Indicate whether the planning process uses decimal or whole number values when calculating planned order

quantities or repetitive rates. |

When this option is checked, decimal values round up (never down) to the next whole number. The planning process carries any excess quantities and rates forward into subsequent periods as additional supply. | ||

| Acceptable Early Days 2 | Enter the number of days before which the planning process will not reschedule orders. | The planning process only suggests rescheduling out if the new calculated order date is later than the original order due date plus the acceptable early days; the new calculated order does not violate the order of current scheduled receipts.

This applies to discrete items only. |

||

| Calculate | Indicate whether | On the Planning Detail Report, | ||

| ATP 3 | to calculate and | ATP is calculated as | ||

| print available to | ATP = Planned production – | |||

| promise (ATP) | committed demand | |||

| on the Planning | ||||

| Detail Report. | ||||

| Reduce MPS | None, Past | Decide when to | None: Do not reduce order | |

| 4 | Due, | reduce master | quantities on the MPS. | |

| Demand | production | Past Due: Reduce order quantities | ||

| Time Fence, | schedule (MPS) | on MPS entries to zero when the | ||

| Planning | quantities to | entry is past due. | ||

| time Fence | zero. | Demand Time Fence: Reduce | ||

| order quantities on MPS entries to | ||||

| zero when the due date moves | ||||

| inside the demand time fence. | ||||

| Planning time Fence: Reduce | ||||

| order quantities on MPS entries to | ||||

| zero when the due date moves | ||||

| inside the planning time fence. |

| Attribute | Valid

values |

Purpose | Comment | Setup |

| Planning | Cumulative | Determine a | Planning calculates the planning | |

| Time Fence | mfg. lead | point in time | time fence as the plan date (or the | |

| Days 5 | time, | inside which | next workday if the plan is | |

| Cumulative | certain | generated on a non workday) plus | ||

| total lead | restrictions on | the value entered here. | ||

| time, Total | planning | Cumulative mfg. lead time: The | ||

| lead time, | recommendations | cumulative manufacturing lead | ||

| User– | apply. | time for the item. | ||

| defined | Cumulative total lead time: The | |||

| total manufacturing lead time for | ||||

| the item. | ||||

| Total lead time: The total lead time | ||||

| for the item. | ||||

| User–defined: The value you enter | ||||

| for Planning Time Fence | ||||

| Days. | ||||

| Demand | Cumulative | Determine a | Used to reduce the risk of carrying | |

| Time Fence | mfg. lead | point in time | excess inventory. | |

| Days | time, | inside which the | Planning also uses the demand | |

| Cumulative | planning process | time fence when loading master | ||

| total lead | ignores forecast | schedules. The demand time fence | ||

| time, Total | demand and | is calculated as the start date of the | ||

| lead time, | considers only | master schedule load plus the value | ||

| User– | sales order | entered. | ||

| defined | demand when | Calculate the demand time fence as | ||

| calculating gross | the plan date (or the next workday | |||

| requirements. | if the plan is generated on a non | |||

| workday) plus: | ||||

| Cumulative mfg. lead time: The | ||||

| cumulative manufacturing lead | ||||

| time for the item. | ||||

| Cumulative total lead time: The | ||||

| total manufacturing lead time for | ||||

| the item. | ||||

| Total lead time: The total lead time | ||||

| for the item. | ||||

| User–defined: The value you enter | ||||

| for Planning Time Fence | ||||

| Days. |

| Attribute | Valid

values |

Purpose | Comment | Setup |

| Release Time | Cumulative | Determine a | No material availability check is | |

| Fence Days 6 | mfg. lead | point in time | performed before WIP jobs are | |

| time, | inside which | released. | ||

| Cumulative | planned orders | Calculate the release time fence as | ||

| total lead | for discretely | the plan date (or the next workday | ||

| time, Total | planned items are | if the plan is generated on a non | ||

| lead time, | automatically | workday) plus the value entered | ||

| User– | released as WIP | here. | ||

| defined, Do | jobs or purchase | Cumulative mfg. lead time: The | ||

| not auto– | requisitions. | cumulative manufacturing lead | ||

| release, Do | time for the item. | |||

| not release | Cumulative total lead time: The | |||

| (Kanban) | total manufacturing lead time for | |||

| the item. | ||||

| Total lead time: The total lead time | ||||

| for the item. | ||||

| User–defined: The value you enter | ||||

| for Planning Time Fence | ||||

| Days. | ||||

| Do not auto–release: The item | ||||

| cannot be auto–released. | ||||

| Do not release (Kanban): For | ||||

| Kanban items prevent release of | ||||

| planned orders manually or | ||||

| automatically. | ||||

| Substitution | Cumulative | Calculates until what time a substitute can be considered for an item. | Cumulative mfg. lead time: The | |

| Window | mfg. lead time

Cumulative |

cumulative manufacturing lead time

for the item. |

||

| total lead | Cumulative total lead time: The total | |||

| time | manufacturing lead time for the item. | |||

| Total lead | Total lead time: The total lead time for | |||

| time | the item. | |||

| User-defined | User-defined: The value you enter. |

Recent Posts